CONSTRUCTING A WORKING PLATFORM WITH TENSAR INTERAX

PROJECT DESCRIPTION

Seymour Civil Engineering approached Tensar at tender stage to value engineer a large piling platform where a 30kN/m biaxial geogrid had initially been proposed to reinforce the platform.

The initial design used illustrative calculations in BR470, proposing to use a 30kN/m biaxial geogrid. Seymour Civils were looking for a competitive advantage in their tender and this solution did not offer sufficient project savings, therefore, a technical and commercial alternative was needed. The project required excavation into existing ground and so minimising this would be beneficial to the cost and sustainability credentials.

OUR SOLUTION

A Mechanically Stabilised Layer (MSL) incorporating Tensar InterAx geogrid was designed using the Tensar T-Value methodology. This methodology, developed following guidance from the BRE (authors of BR470) has been shown to offer engineers a viable and realistic alternative to the often-conservative BR470 approach. This solution reduced the platform thickness by approximately half which gave the contractor a commercial advantage at tender stage due to the significant cost, time and carbon savings proposed by Tensar.

PRODUCT USED

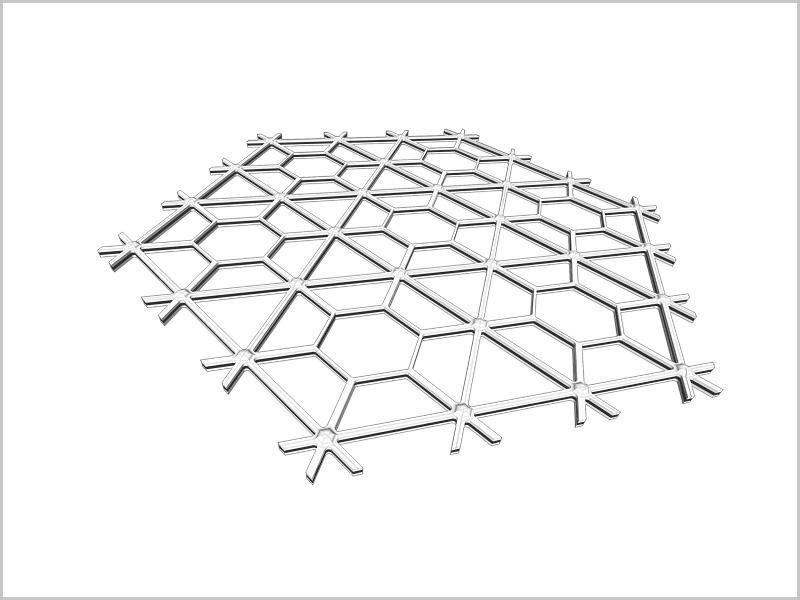

Tensar® InterAx® Geogrid

- Speeds up construction, saving up to 70% in aggregate section reduction

- Optimised geometry design for maximum confinement and compaction of granular fill, creating the most efficient mechanically stabilised layer (MSL)

- Improves compaction and restrict the movement of the particles over time, retaining the stiffness long term and further enhancing performance of the MSL

- Results in a more resilient solution that will withstand severe weather events, the increasing impact of climate change, and other challenging environmental conditions

- Improves interaction between the geogrid and aggregate for better performance

- Less aggregate is required to meet project requirements, which leads to savings on cost, time and carbon emissions

- Ideal for subgrade stabilisation, roads, heavy-duty pavements, and working platforms