STABILISING WEAK GROUNDS AT WOODSMITH MINE WITH TENSAR INTERAX

PROJECT DESCRIPTION

Woodsmith Mine near Whitby extracts potash and other minerals used in the production of fertiliser products. The overall investment of £2.2 billion means the project is of strategic importance to the contractor, Strabag and the wider North Yorkshire region creating up to 2,500 jobs.

The customer needed to construct the site welfare village and to create a lay down area to support heavy construction vehicles and equipment. Initially, however, the lay down area consisted of weak subgrade soils, which presented a challenge in developing a sustainable, cost-effective solution.

OUR SOLUTION

The solution was Tensar’s mechanically stabilised layer (MSL), using the newly introduced Tensar InterAx geogrid.

This gave the contractor even more confidence to use 6F2 recycled fill material whist maintaining trafficking performance. In turn, this provided support for heavy construction vehicles and equipment over previously weak ground.

PRODUCT USED

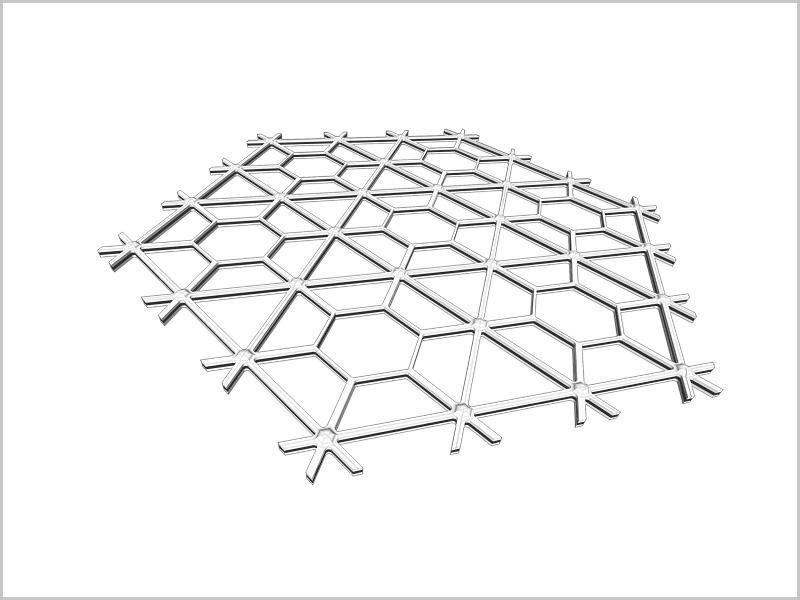

Tensar® InterAx® Geogrid

- Speeds up construction, saving up to 70% in aggregate section reduction

- Optimised geometry design for maximum confinement and compaction of granular fill, creating the most efficient mechanically stabilised layer (MSL)

- Improves compaction and restrict the movement of the particles over time, retaining the stiffness long term and further enhancing performance of the MSL

- Results in a more resilient solution that will withstand severe weather events, the increasing impact of climate change, and other challenging environmental conditions

- Improves interaction between the geogrid and aggregate for better performance

- Less aggregate is required to meet project requirements, which leads to savings on cost, time and carbon emissions

- Ideal for subgrade stabilisation, roads, heavy-duty pavements, and working platforms