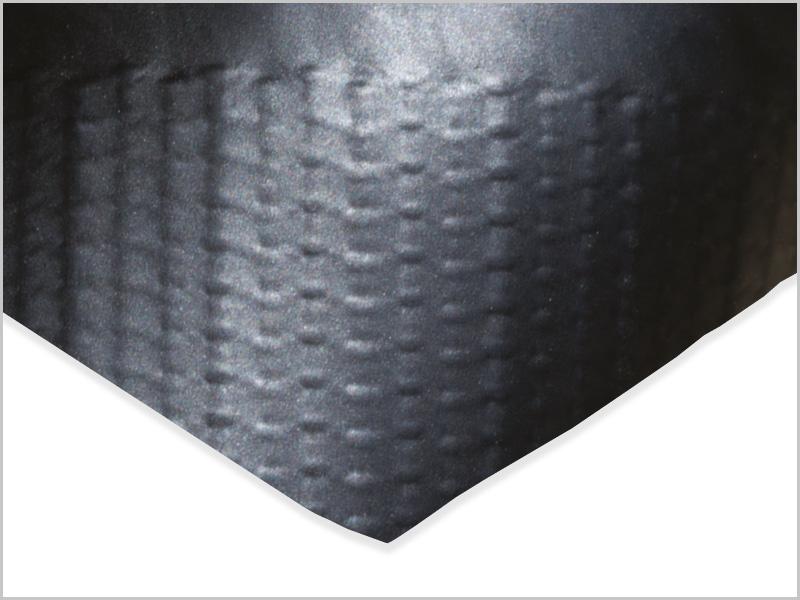

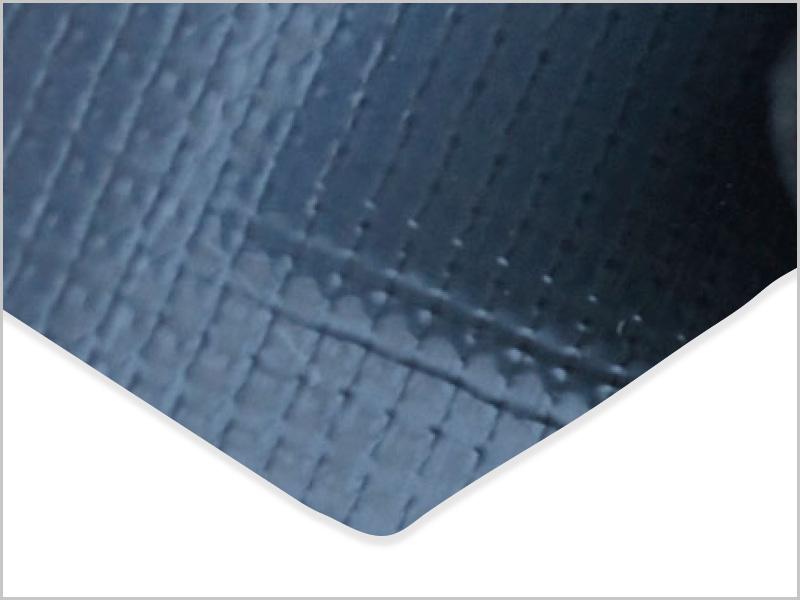

Geomembranes (GMBs) are best-in-class polyethylene (PE) resins coupled with premium antioxidant packages using the most advanced in-house flat-die technology. This results in high quality and consistent PE geomembranes with maximum durability and long term performance. They achieve the highest stress crack resistance values in the industry, together with unrivalled mechanical and chemical properties to be the best liner for any containment application.

The range includes high density polyethylene (HDPE) and linear low density polyethylene (LLDPE) impermeable barriers for containment of water and waste, with a focus on proving longevity when immersed in high risk contaminated solids and liquids that result from mining and waste processes.

WHY CHOOSE HIGH DENSITY POLYETHYLENE GEOMEMBRANE?

- Ability to provide a solution that optimises cost and maximises longevity

- Excellent resistance to chemistry

- Maintains performance over time

- Resistant to high stress and strain

- Rapid lead times compared to other premium suppliers in the industry, ensuring consistent supply and less down time during construction

- Ability to carry out R&D in-house with the Geosynthetic Research, Innovation & Development (GRID) Laboratory, including immersion testing and cushion analysis to prove performance in harsh environments

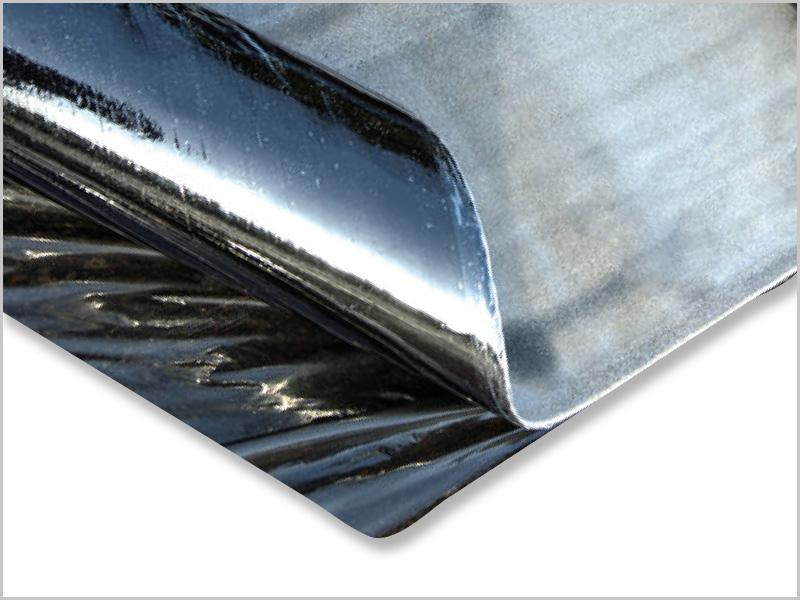

- Option to include coloured geomembranes and/or a conductive layer for spark testing of defects or holes which may result from installation damage or manufacturing defects

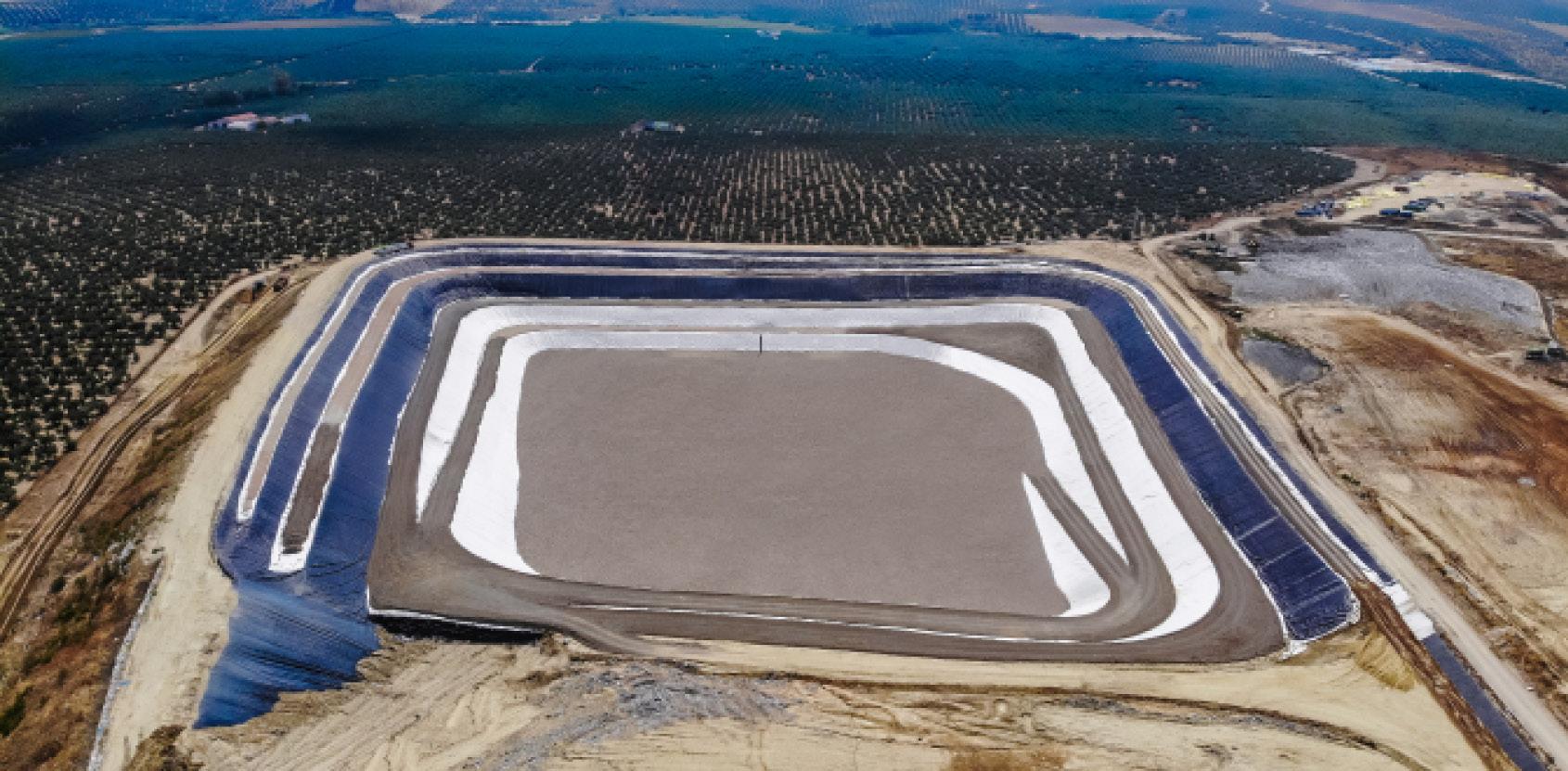

WASTE

When it comes to waste containment, it is essential to prevent the potential contamination of soils, underground and surface waters, and the odours caused by leachates, gases and volatile waste. Our range of geomembranes provide secure containment for storing all types of waste, including municipal, hazardous and industrial solid and liquid waste.

The HDPE range is specifically formulated for Australian industry standards, including the Victorian Best Practice Environmental Management’s (BPEMs) rigorous guidelines.

MINING

Mining processes produce some of the harshest by-products known and as such require stringent assessment when selecting suitable geomembranes for long term containment. The LLDPE and particularly the HDPE range, are often ideal for these harsh liquids, where degradation is accelerated through a combination of heat, UV exposure and chemical interactions.

Relying on GRI GM13 (industry HDPE standard) is not recommended in higher risk applications observed within the mining sector. As such, site specific immersion testing and looking at historical evidence and performance is critical to evaluate and select the most appropriate and cost effective lining material. We offer the right solution to contain any mining liquids, with proven long-term performance even when used in combination with other geosynthetic products, such as cushion geotextiles or geocomposites.

Specific applications in mining include heap leach pads, tailings dams, process water ponds, evaporation ponds and tanks.

WATER

The water industry is a broad sector and can expose liners to harsh environments and chemistry such as chlorine, hydrocarbons, petrochemical, and a range of other common contaminants. Both the HDPE and LLDPE geomembranes are common high-end options in this sector due to the extended design life resulting from the improved performance characteristics, including stress crack resistance (SCR) and superior antioxidant (AO) packages.

Most water applications undergo full UV exposure which when combined with chemistry and thermal damage risk, means a superior HDPE or LLDPE should be considered. Specific applications in water include potable water dams, irrigation dams, agricultural ponds, canals and tanks.

INSTALLATION

- Typical HDPE and LLDPE installation involves heat and pressure welding by suitability trained PE lining contractors

- In the case welding is not required, loose overlaps may be acceptable but wind uplift and exposure risk should be considered

- Anchor trenches to fix the geomembranes down are common in most containment applications and should be designed for the site conditions including wind uplift and length of the exposed geomembrane

- For further information, download the installation and conductive GMB installation guidelines

APPLICATIONS