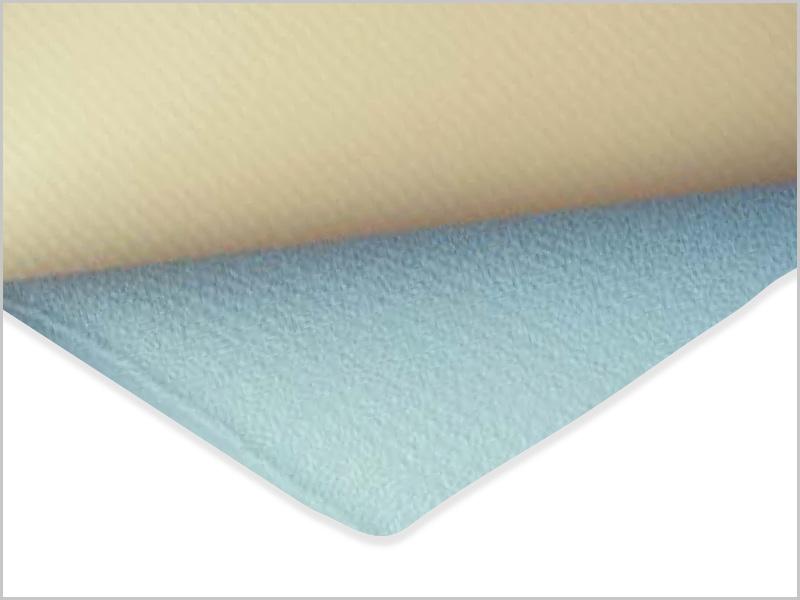

Tank liner geomembranes are engineered for primary and secondary containment of fuels and other aggressive products, it is available in ether and ester versions. Ether-based Coolthane offers more stability when exposed to water and has good resistance to petroleum hydrocarbons. Ester-based Coolthane has excellent resistance to petroleum hydrocarbons.

Coolthane can withstand a broad range of chemicals and fuels with little or no deterioration of physical properties and offers a wide variety of reinforcements dependent on the application. The reinforcements range from a simple scrim design to rip-stop and heavy-duty base fabrics with over 1,000 pounds (453 kilo) tensile strength, and are available in a wide variety of choices, including polyester, nylon, and aramid.

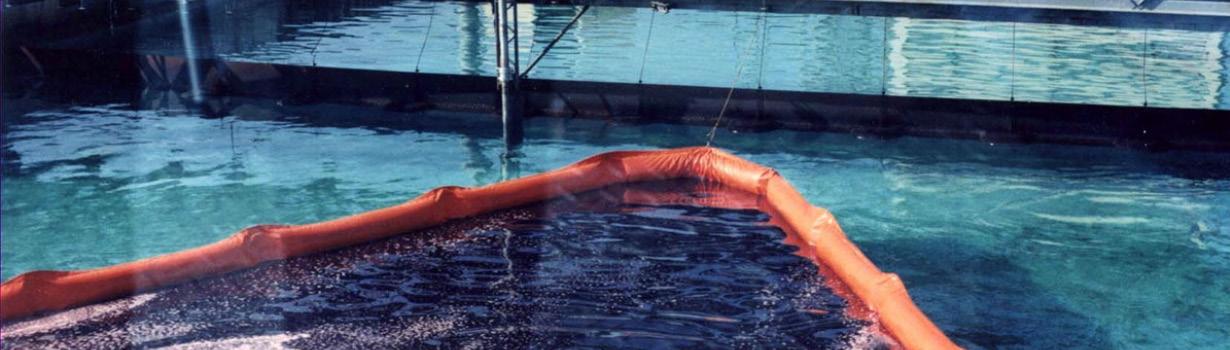

The fabric in Coolthane is designed to meet the most demanding applications that include high-strength, US military-specified liners and fuel and water pillow tanks, collapsible/portable tanks, chemical suits, dock shelters, water bladder materials, inflatable boats, tank seals, fuel cells for race cars, and oil boom materials.

WHY CHOOSE TANK LINER GEOMEMBRANE?

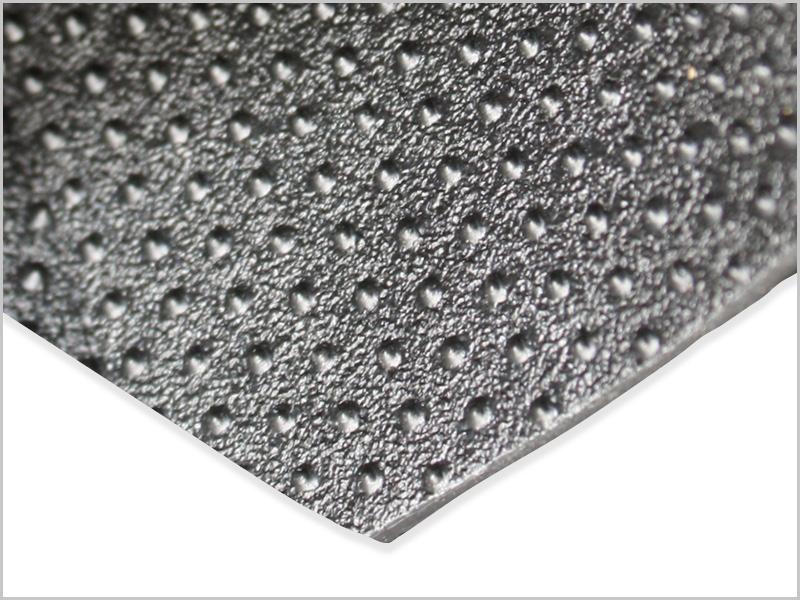

- Highly resistant to punctures, tears, abrasions, UV, chemical and fuel

- Excellent in low temperature environments, as low as -18°C

- Unique melt characteristics allow it to be fabricated using radio- frequency, thermal and ultrasonic methods