FOUNDATION SUPPORT AT EASTLEIGH RAILWAY DEPOT WITH TENSAR INTERAX

PROJECT DESCRIPTION

After encountering weaker than expected subgrade soil conditions, a solution was required to address initial construction activities as well as achieve target levels of support for the permanent works.

Tensar were contacted by the client to address challenges with subgrade conditions that were much weaker than expected from initial project documentation (CBR 0.8% vs an expected minimum of 3.4%). Foundation subgrade improvement was required to support concrete slab construction, alongside a working platform and haul road to give construction access over the weak ground.

OUR SOLUTION

A Tensar Mechanically Stabilised Layer (MSL) incorporating Tensar InterAx geogrid was provided, considering both the varying loading conditions and performance criteria to suit the construction sequence. Admissible bearing pressures were provided for using the MSL as a working platform in the construction phase, with additional advice regarding maintenance and validation testing prior to its permanent use beneath a ground bearing slab. The Tensar MSL achieved the required levels of support throughout construction.

PRODUCT USED

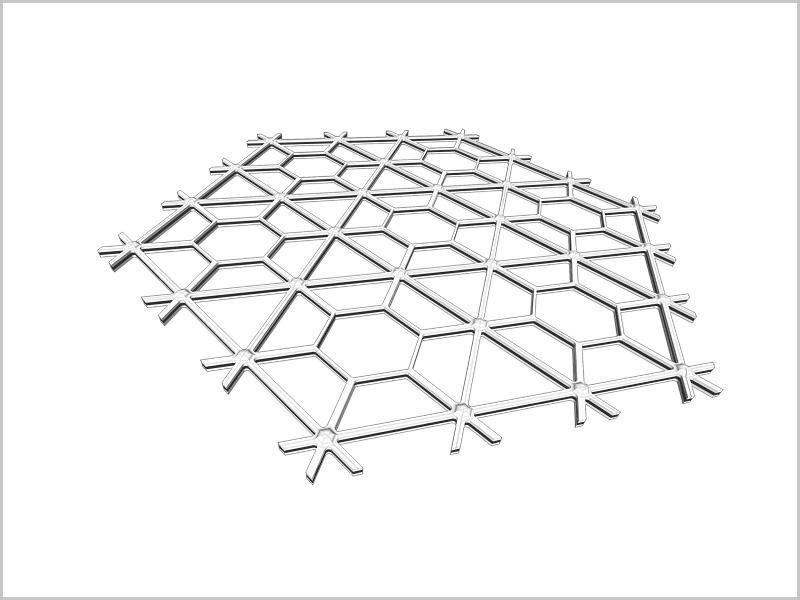

Tensar® InterAx® Geogrid

- Speeds up construction, saving up to 70% in aggregate section reduction

- Optimised geometry design for maximum confinement and compaction of granular fill, creating the most efficient mechanically stabilised layer (MSL)

- Improves compaction and restrict the movement of the particles over time, retaining the stiffness long term and further enhancing performance of the MSL

- Results in a more resilient solution that will withstand severe weather events, the increasing impact of climate change, and other challenging environmental conditions

- Improves interaction between the geogrid and aggregate for better performance

- Less aggregate is required to meet project requirements, which leads to savings on cost, time and carbon emissions

- Ideal for subgrade stabilisation, roads, heavy-duty pavements, and working platforms