RAILWAY SUB-BALLAST STABILISATION WITH TRIAXIAL GEOGRID

PROJECT DESCRIPTION

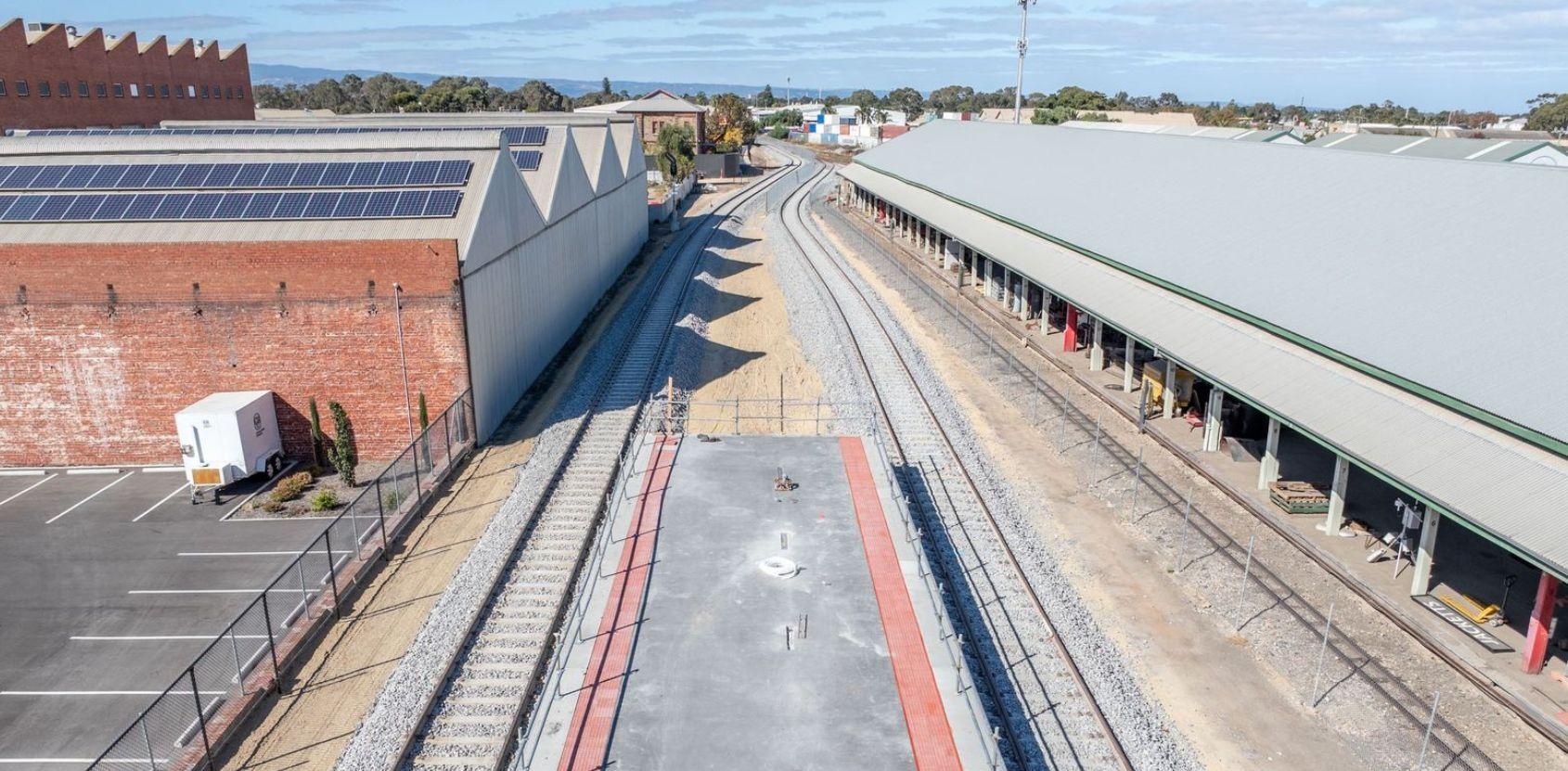

The Department for Infrastructure and Transport’s Port Dock Railway Line Project involved re-establishing the 1 km rail line and train station, which were previously decommissioned in 1981. It provides rail services for those who already call the area home and the many more set to live, work and visit Port Adelaide.

The onsite subgrade presented challenges due to its softness, with a California Bearing Ratio (CBR) of only 2%. Conventional methods for improving the subgrade would have necessitated excavating and replacing the subgrade to a depth of 800-1000mm with structural fill (CBR = 8%).

In response to these challenges, the Public Transport Project Alliance (PPTA) sought an alternative solution involving the use of geosynthetics to enhance the bearing capacity of the track bed and address the foundational issues, thereby ensuring the successful completion of the rail line extension.

OUR SOLUTION

Geofabrics recommended a mechanically stabilised trackbed using triaxial with a well-graded granular material to the client’s engineer. This solution was 500mm thinner compared to the conventional remediation strategy.

Triaxial geogrid and Bidim Green non-woven geotextile (A24) were rolled out onsite and overlapped. A 300mm thick layer of well-graded aggregate, PM3/40 was placed above triaxial geogrid to create a mechanically stabilised structural fill layer, with compaction carried out to meet the project requirements. In total, 14 rolls of triaxial geogrids were installed, covering 4000m². The Geofabrics team were available onsite to provide technical assistance during the installation.

By adopting a mechanically stabilised track bed, the required excavation depth was reduced by 500mm compared to the conventional treatment with a CBR of 8%.

Construction of the railway line has been completed.

PRODUCT USED

Bidim® Green Non-Woven Geotextile

• A strong three-dimensional structure with high elongation and equal biaxial strength properties in both directions

• Made with a combination of recycled PET and virgin plastic materials

• Provides excellent filtration, separation, drainage and protection performance

• Reduced need for quarried fill materials and reduced construction times

SIMILAR PRODUCT

Triaxial Geogrid

• A multi-axial geogrid made from punched polypropylene sheets, forming a unique hexagonal structure with triangular apertures that confine and interlock with aggregate for soil stabilisation and ground improvement

• Reduces aggregate layer thickness by up to 50% without compromising performance, lowering excavation and fill costs

• Enhances layer stiffness to allow the use of lower quality or recycled fill materials, reducing material costs

• Speeds up installation, offering a fast, cost-effective stabilisation solution for roads, working platforms and heavy-vehicle pavements

DISCLAIMER - The images depicted in the photographs on this page are similar to the Geofabrics' products listed but they are not the same.